Workworking Machinery

- Furniture production line

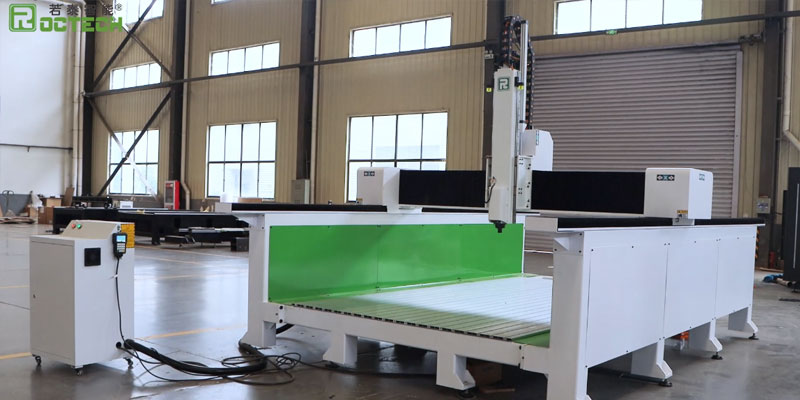

- Roctech Master Series

- Roctech Pro Series

- ATC CNC Routers

- CNC Wood cutting Routers

- Edge Banding Machines

- CNC Drilling machines

- 4 Axis CNC Router

- 5 Axis CNC Router

- Other woodworking machinery

- CNC Router for Sign Makers

- Big CNC for Molds (EPS)

Comment content:Your machine is of good quality, I like it very much, it is easy to operate, my workers can learn it easily. The cutting speed of the template is very fast, which saves me time. I hope this new partner can help me make more money