The cutting capacity of ROCLAS machines is impressive, available in multiple size configurations including 3m×1.5m, 4m×2m, 6m×2m, and 6m×2.5m. This range of options allows businesses to select the most suitable model for their specific production needs. Whether working with smaller precision components or larger panels, there's a ROCLAS machine sized appropriately for the task. The flexibility in machine sizes ensures customers don't pay for unnecessary capacity while still having room for future growth.

Laser power output ranges from 500W to 6000W, providing versatility for different material types and thicknesses. Lower power settings work well for thinner materials and more delicate work, while higher power options handle thicker metals and faster cutting speeds. This power flexibility makes the machines adaptable to various production requirements within a single facility. The ability to adjust power settings also contributes to energy efficiency, as operators can use only the power needed for each job.

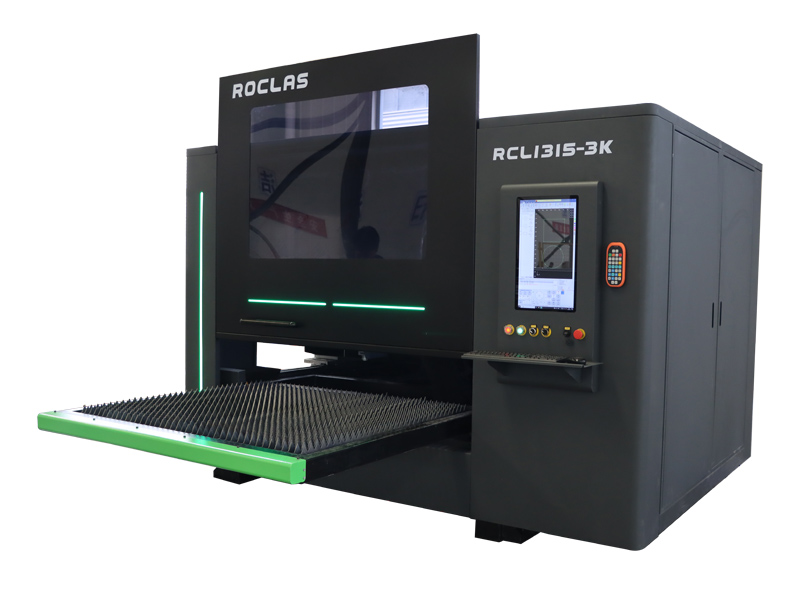

Precision is a standout feature of ROCLAS fiber laser cutters. The worktable demonstrates excellent axial accuracy of ±0.03mm and repeat positioning accuracy of ±0.02mm. These tight tolerances ensure consistent, high-quality cuts across production runs. Such precision is particularly valuable for applications where components must fit together perfectly or where edge quality is critical. The machines maintain this accuracy even during continuous operation, thanks to their stable mechanical structure.

Power requirements are standard for industrial equipment at 380V 50Hz, making installation straightforward in most manufacturing facilities. The IP54 protection level indicates good resistance to dust and water splashes, suitable for typical workshop environments. These specifications reflect thoughtful engineering that considers real-world operating conditions while maintaining safety standards.

Operation of ROCLAS fiber laser cutting machines is designed to be user-friendly. The intuitive control systems reduce training time and minimize operational errors. Even less experienced operators can quickly learn to produce quality results. This ease of use translates to lower labor costs and reduced downtime for staff training. The machines' reliability further contributes to smooth production flow with minimal interruptions.

Maintenance requirements are reasonable, with accessible components that simplify routine servicing. The robust construction means fewer breakdowns and lower repair costs over the machine's lifespan. These factors contribute to the overall cost-effectiveness of the equipment. When maintenance is needed, ROCLAS provides reliable support and spare parts availability to minimize downtime.

Energy efficiency has been carefully considered in the machine design. Fiber laser technology itself is more energy-efficient than many alternative cutting methods. Combined with smart power management features, ROCLAS machines help reduce electricity costs compared to less efficient equipment. This efficiency contributes to both environmental benefits and lower operating expenses for the business.

The cutting quality achieved by ROCLAS machines meets high industrial standards. Clean edges typically require little or no additional finishing work, saving time and labor costs. The consistent results make the machines suitable for both prototype development and full-scale production. Users can expect reliable performance that maintains quality standards throughout long production runs.

For businesses evaluating laser cutting solutions, ROCLAS machines represent an attractive balance of performance and affordability. The technology offers real productivity improvements while keeping capital investment reasonable. The return on investment often justifies the purchase through enhanced capabilities and efficiency gains. Many users find the machines pay for themselves within a practical timeframe through increased output and reduced waste.

Applications for ROCLAS fiber laser cutters span numerous industries including metal fabrication, automotive components, electronics, and industrial machinery. The machines handle various materials including carbon steel, stainless steel, aluminum, and other metals. This versatility makes them valuable assets in diverse manufacturing environments. The ability to process different materials with a single machine adds to their cost-effectiveness.

After-sales support is an important consideration when investing in laser cutting equipment. ROCLAS provides comprehensive service and technical assistance to help customers maximize their machine's potential. This support network is valuable for troubleshooting, maintenance advice, and operational optimization. Knowing that professional help is available when needed gives buyers additional confidence in their purchase.

ROCLAS fiber laser cutting machines offer manufacturers an efficient, precise, and economical cutting solution. Their combination of performance characteristics and reasonable pricing makes them particularly suitable for businesses looking to upgrade their capabilities without excessive capital expenditure. The machines' reliability and low operating costs contribute to their value proposition. For companies seeking to improve their cutting operations with modern technology, ROCLAS equipment deserves serious consideration as a practical and productive option. Interested parties can contact ROCLAS for more detailed technical information and personalized recommendations based on their specific production requirements.

Looking for more information about our CNC machines and services? Contact us today.

Contact

Previous:ROCTECH CNC Six sided Drilling Center Helps Modern Manufacturing Enterprises Develop Faster

Next:ROCTECH CNC Engraving Machines Suit Different Needs and Budgets