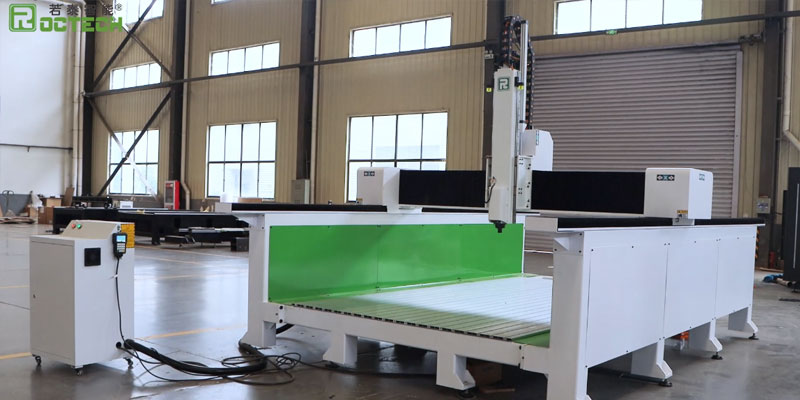

ROCTECH has established itself as a trusted manufacturer of high-performance CNC machines, serving clients across more than 20 countries worldwide. Our 4-axis machining center represents the perfect blend of advanced engineering and practical functionality, designed to handle complex machining tasks with precision and efficiency.

The standout feature of this machine is its true 4-axis simultaneous movement capability, enabling sophisticated contour machining that traditional 3-axis machines cannot achieve. The spindle can rotate ±90 degrees, allowing for side milling, drilling, and cutting operations without repositioning the workpiece. This unique functionality makes it ideal for processing irregular surfaces and complex geometries that require multi-angle machining in a single setup.

What truly sets this machine apart is its innovative turret-style tool changer, a significant upgrade from conventional systems. The circular tool magazine holds multiple tools and enables rapid automatic tool changes, reducing idle time between operations. This efficient design can save up to 30% in processing time compared to standard machines, directly improving production throughput and lowering operational costs.

The machine maintains ROCTECH's reputation for stability and reliability. Built with high-quality components and precision engineering, it delivers consistent performance even during extended operation periods. The rigid construction minimizes vibration, ensuring accurate cuts and prolonging tool life. Users can expect the same dependable operation that has made ROCTECH machines popular in diverse industrial applications worldwide.

Practical features enhance the machine's usability. The user-friendly control system simplifies operation while providing advanced programming capabilities. Maintenance is straightforward, with accessible components designed for easy serviceability. These thoughtful design elements contribute to lower long-term operating costs and reduced downtime.

ROCTECH maintains competitive pricing without compromising quality. Our direct manufacturing approach allows us to offer professional-grade 4-axis machining capabilities at accessible price points. The machine represents excellent value, particularly when considering its time-saving features and energy-efficient operation that reduces power consumption.

This 4-axis machining center suits various applications including:

Complex mold and die manufacturing

Precision aerospace components

Automotive parts production

Architectural millwork

Artistic and decorative engraving

Prototype development

Our global customer base includes manufacturers in metalworking, wood processing, sign making, and other industries that require advanced machining capabilities. Client feedback consistently praises the machine's reliability, precision, and the productivity gains achieved through its efficient design.

ROCTECH provides complete support from selection through operation. Our technical team offers personalized consultation to ensure the machine meets your specific requirements. We provide comprehensive after-sales service including installation support, operator training, and maintenance guidance to maximize your investment.

For businesses considering adding 4-axis capabilities, ROCTECH's solution offers compelling advantages:

True 4-axis simultaneous machining

±90° spindle rotation for complex geometries

Faster processing with automatic tool changing

Proven reliability and stability

Energy-efficient operation

Competitive pricing

Global service support

To learn more about this 4-axis machining center or other ROCTECH CNC products, visit our official website. You can submit inquiries through our contact form, email our sales team, or call directly for personalized assistance. We're committed to helping you find the right CNC solution to enhance your manufacturing capabilities.