When I first saw the ROCTECH Auto Feeding and Nesting Center in action at a furniture factory in Milan, what struck me wasn't just the humming efficiency - it was how casually the staff interacted with this technological marvel. That's the essence of this system: industrial-grade performance wrapped in astonishing simplicity.

The magic starts with its triple-layered intelligence. Unlike traditional CNC machines that require specialized operators, our system adopts what we call "three-click workflow" - any team member can master basic operations within two hours. The touchscreen interface feels more like using a smartphone than industrial equipment. Last quarter, a door manufacturer in Texas reduced their training costs by 68% after switching to this system.

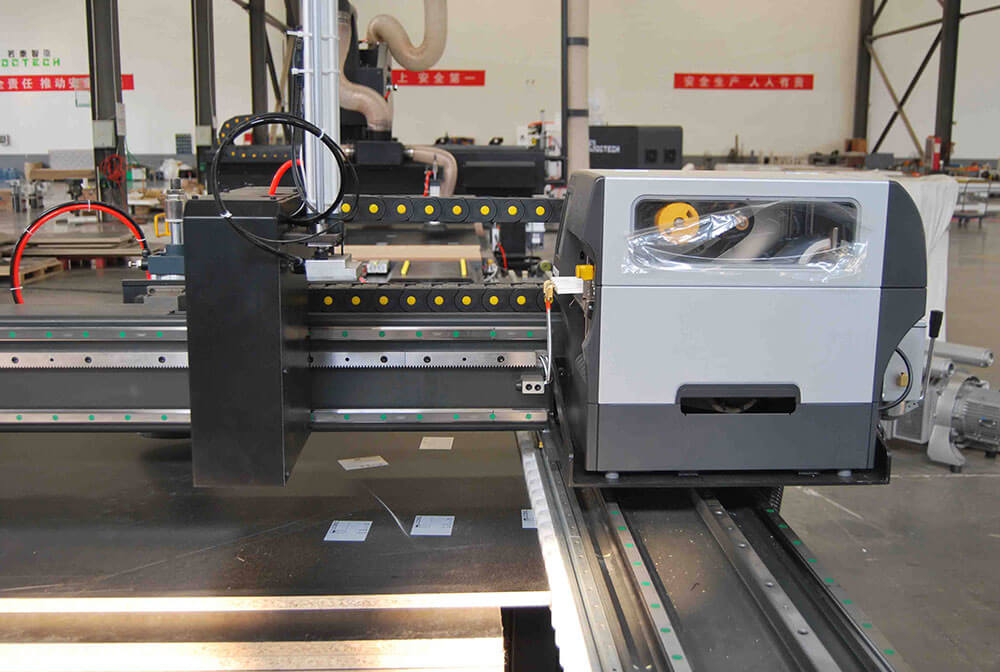

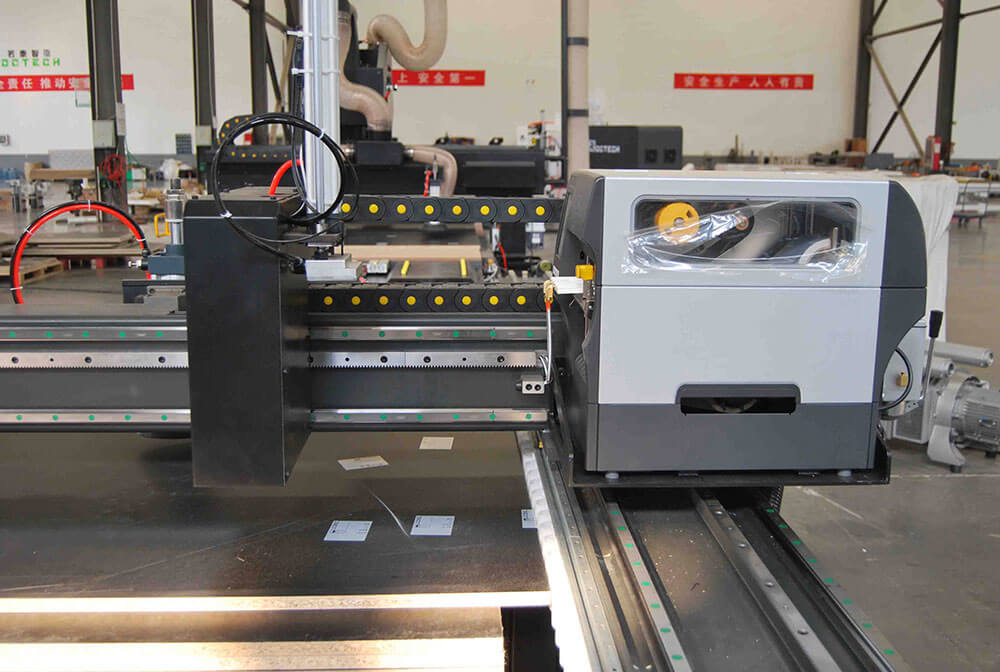

What really makes buyers nod in approval is the autonomous material handling. From automatically loading full sheets to intelligently nesting parts (we've achieved 92% material utilization in field tests), then unloading finished components - all without human intervention. The Japanese Yaskawa servos work in perfect sync with the Italian HSD spindle (with automatic tool changer), delivering positioning accuracy of ±0.02mm even during continuous 24/7 operation.

We've solved the small-part vibration headache too. The double-layer vacuum table isn't just another aluminum platform - its zone-controlled suction adapts to piece sizes dynamically. During a recent automotive interior project in Germany, operators reported zero part displacement even when cutting intricate 5mm acoustic foam components.

Reliability comes from its "best-in-class" DNA. The Italian Osai-based Syntec controller processes optimization algorithms 40% faster than industry average, while the Apex reducers ensure smooth power transmission. Maintenance? Our self-diagnostic system predicts 83% of potential issues before they occur.

For those wondering about integration, here's the straightforward answer: it works with your existing workflow. Whether you're processing MDF for retail displays or aluminum composite for signage, the system auto-adjusts parameters. A packaging plant in Thailand connects three of these units with their ERP system - their production manager calls it "set-and-forget automation".

Curious about what it could do for your specific operation? Our engineers speak the language of practical manufacturing, not just technical jargon. Share your material types, typical sheet sizes, and daily output goals - we'll provide realistic throughput projections within 24 hours. There's no "one-size-fits-all" pitch here, just honest conversations about solving your particular production challenges.

Looking for more information about our CNC machines and services? Contact us today.

Contact

Previous:Introducing ROCTECH CNC Six Side Drilling Center

Next:ROCTECH CNC Routers: Precision, Innovation, and Reliability for Your Business