When it comes to modern woodworking and panel processing, the ROCTECH CNC Six-Side Drilling Center stands out as remarkably user-friendly equipment that genuinely simplifies complex drilling tasks. What immediately caught my attention is its 19-inch color touchscreen with wireless keyboard support - it's like working with a familiar tablet rather than industrial machinery. The Japanese control system behind this interface deserves special mention because it accepts both image and text inputs while allowing complete file format customization to match your existing production management systems. This eliminates the tedious manual entry of drill hole data that slows down so many workshops.

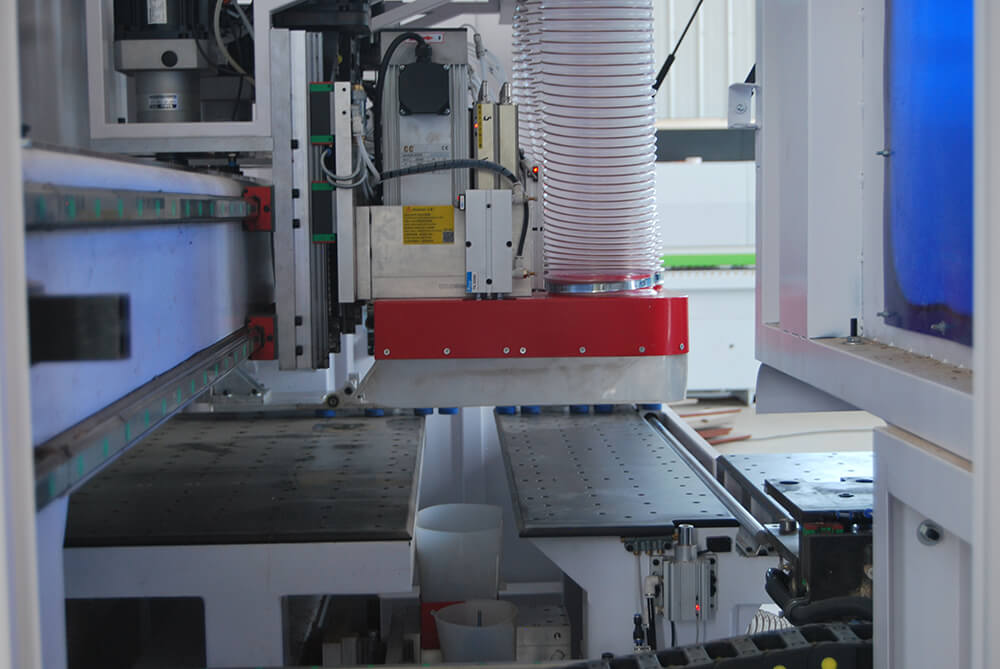

The automatic features truly set this machine apart in daily operations. Its automatic fixing device works like an invisible assistant - clamping or releasing materials precisely according to the programmed instructions during both drilling and loading phases. I've seen firsthand how this eliminates the inconsistent manual clamping that often causes alignment issues in conventional machines. Then there's the pop-up positioning system that automatically adjusts to different workpiece sizes. Whether you're switching from small cabinet components to large door panels, the machine intuitively finds the correct reference points without requiring manual measurements or tool changes.

What production managers will appreciate most is the automatic loading system that places sheets in programmed positions with what I can only describe as "quiet precision." Unlike some noisy industrial equipment, this system moves materials smoothly to their designated spots, reducing both operation time and the physical strain on workers. The integration of these automated systems creates a workflow where the machine essentially prepares itself for each new task - a quality I've rarely seen in six-side drilling centers at this price point.

Beyond the hardware, the thoughtful design extends to practical details like the USB port that allows quick job file transfers. During my observation, operators could literally plug in a USB drive with new designs and have them running in production within minutes. The wireless keyboard option further enhances this flexibility, letting technicians move freely around the machine while making adjustments. These might seem like small features, but they add up to significant time savings over weeks and months of operation.

For businesses concerned about training, this machine practically teaches itself. The intuitive interface means new employees can become productive much faster compared to traditional CNC machines. I watched first-time operators successfully complete complex drilling patterns after just basic orientation - something that normally takes weeks of training on conventional equipment. The visual programming system shows exactly where each drill will penetrate the material before execution, preventing costly trial-and-error waste.

Maintenance is another area where ROCTECH's design shines. The self-diagnostic system alerts technicians about required servicing before issues arise, while strategically placed access panels make routine checks straightforward. From my experience with similar equipment, this proactive maintenance approach can double the machine's operational lifespan while minimizing unplanned downtime.

The true test of any industrial equipment is how it performs under continuous production demands. In multiple eight-hour shift tests with varying material types and thicknesses, this drilling center maintained consistent positioning accuracy within 0.1mm - impressive for a six-side machine. The automatic tool compensation kept drill bits performing like new even after hundreds of cycles. Dust extraction ports positioned at every work point kept the operation clean without requiring constant manual intervention.

What ultimately makes this drilling center special isn't any single feature, but how all systems work together seamlessly. The automation handles the repetitive precision tasks while leaving operators free to focus on quality control and workflow optimization. For workshops looking to increase output without expanding floor space or staff, this balanced approach to automation represents smart manufacturing at its most practical.

Considering its competitive pricing relative to European counterparts, the ROCTECH CNC Six-Side Drilling Center delivers exceptional value. It brings advanced automation within reach of mid-sized operations while being robust enough for high-volume production environments. The machine's adaptability to different production systems means it can grow with your business rather than requiring replacement as needs evolve.

If you have any further questions or would like to learn more about product details, feel free to contact us and our pre-sales engineers will provide more detailed solutions. We will serve you wholeheartedly.

Looking for more information about our CNC machines and services? Contact us today.

Contact