Products you may want to know about cnc wood furniture design

cnc wood furniture design news

-

Robot ArmThe robot arm can connect to two cutting machinesIt can realize loading and unloading The robot arm loads the panel, and starts processingAfter processing, the panel can be unloade.....2025-03-06 08:49:28

Robot ArmThe robot arm can connect to two cutting machinesIt can realize loading and unloading The robot arm loads the panel, and starts processingAfter processing, the panel can be unloade.....2025-03-06 08:49:28 -

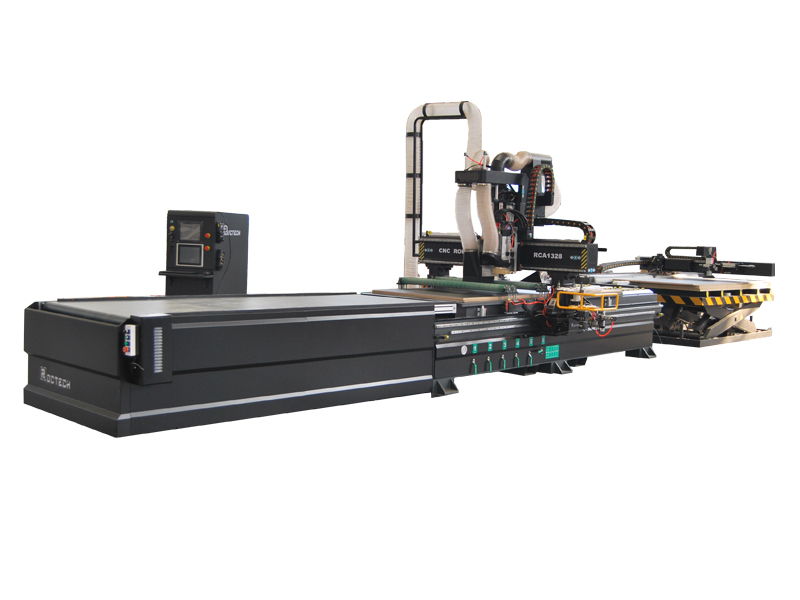

Master RCA2130S-ATC..2024-08-26 08:30:21

Master RCA2130S-ATC..2024-08-26 08:30:21 -

How to adjust the accuracy of the guideway of Roctech CNCIf we use Roctech CNC equipment to process products, we may need to adjust the accuracy of the guide rail. The operator should pay attention to three issues in the process of corre.....2023-03-13 04:40:24

How to adjust the accuracy of the guideway of Roctech CNCIf we use Roctech CNC equipment to process products, we may need to adjust the accuracy of the guide rail. The operator should pay attention to three issues in the process of corre.....2023-03-13 04:40:24 -

What Are Five-axis CNC Engraving Machines?A five-axis CNC engraving machine is a type of CNC machine. It can engrave on the workpiece in five directions at the same time. Like other CNC engraving machines, the basic proces.....2023-05-15 04:12:39

What Are Five-axis CNC Engraving Machines?A five-axis CNC engraving machine is a type of CNC machine. It can engrave on the workpiece in five directions at the same time. Like other CNC engraving machines, the basic proces.....2023-05-15 04:12:39 -

Cookie PolicyRoc-tech wants to ensure that your visit to our website is smooth, reliable, and as profitable as possible. To do so, we use cookies, beacons and similar technologies (collectively.....2023-06-05 09:06:22

Cookie PolicyRoc-tech wants to ensure that your visit to our website is smooth, reliable, and as profitable as possible. To do so, we use cookies, beacons and similar technologies (collectively.....2023-06-05 09:06:22 -

ROCTECH CNC Engraving Machines: Precision, Speed, and Unmatched QualityWhen it comes to CNC engraving machines, quality and reliability are non-negotiable. That’s where ROCTECH stands out. With a relentless focus on product excellence and alignment wi.....2025-12-18 07:46:07

ROCTECH CNC Engraving Machines: Precision, Speed, and Unmatched QualityWhen it comes to CNC engraving machines, quality and reliability are non-negotiable. That’s where ROCTECH stands out. With a relentless focus on product excellence and alignment wi.....2025-12-18 07:46:07 -

How Roctech CNC Can Contribute to Your Manufacturing IndustryThe manufacturing industry is constantly evolving with smarter, more efficient equipment. As a pre-sales engineer at Roctech, I'm pleased to introduce our flagship RCA1224 Auto.....2025-08-02 01:53:44

How Roctech CNC Can Contribute to Your Manufacturing IndustryThe manufacturing industry is constantly evolving with smarter, more efficient equipment. As a pre-sales engineer at Roctech, I'm pleased to introduce our flagship RCA1224 Auto.....2025-08-02 01:53:44 -

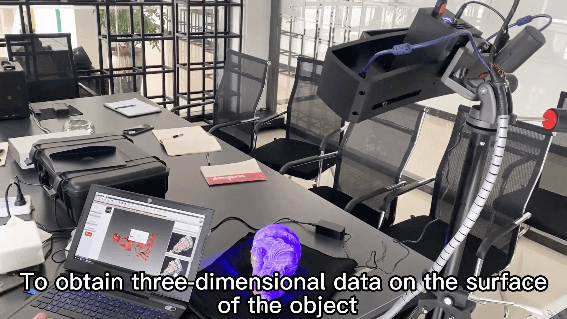

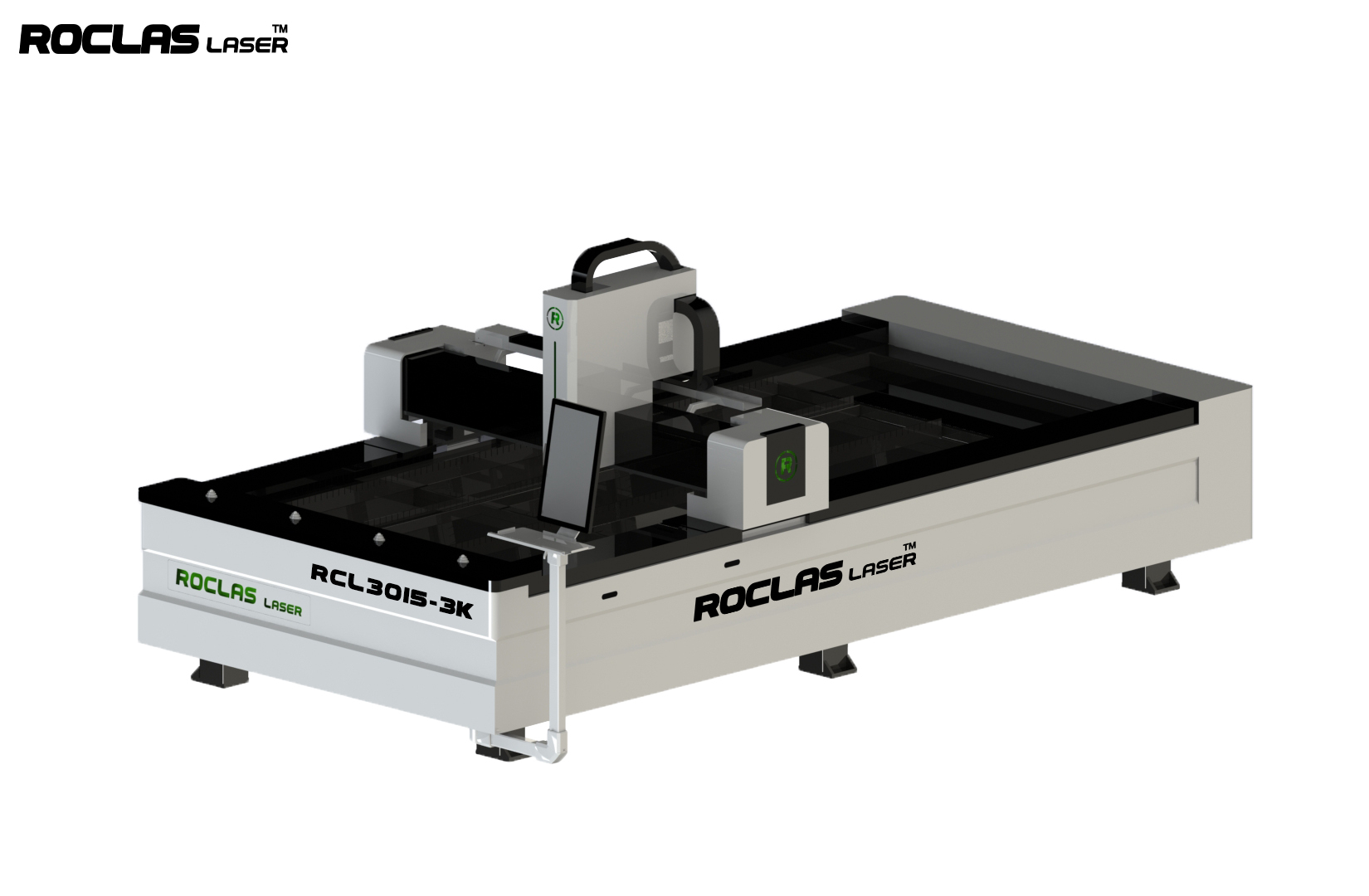

A High-Efficiency Precision Tool for Industry: ROCLAS Fiber Laser Cutting MachineI. IntroductionIn modern industrial production, breakthroughs in precision machining technologies are continuously driving the evolution of manufacturing. As a critical equipment .....2025-04-27 07:45:38

A High-Efficiency Precision Tool for Industry: ROCLAS Fiber Laser Cutting MachineI. IntroductionIn modern industrial production, breakthroughs in precision machining technologies are continuously driving the evolution of manufacturing. As a critical equipment .....2025-04-27 07:45:38 -

router cnc RC1325..2023-04-25 07:55:08

router cnc RC1325..2023-04-25 07:55:08 -

Automatic Labeling and Unloading Center RCA12241Today we will introduce you to Roctech's automatic labeling loading and unloading processing center. This machine can be operated intelligently, humanely and foolishly. Ordinar.....2023-04-04 02:52:59

Automatic Labeling and Unloading Center RCA12241Today we will introduce you to Roctech's automatic labeling loading and unloading processing center. This machine can be operated intelligently, humanely and foolishly. Ordinar.....2023-04-04 02:52:59